Full PU Athletic Running Track Manufacturer

Running tracks with a Full PU Running Track System specification are extremely rare but are considered to be of the highest quality. These surfaces are typically the most expensive due to their superior performance and durability. Known for their impermeability and lack of porosity, polyurethane athletic running track flooring prevents water seepage, ensuring longevity and consistent usability.

Main Construction Steps

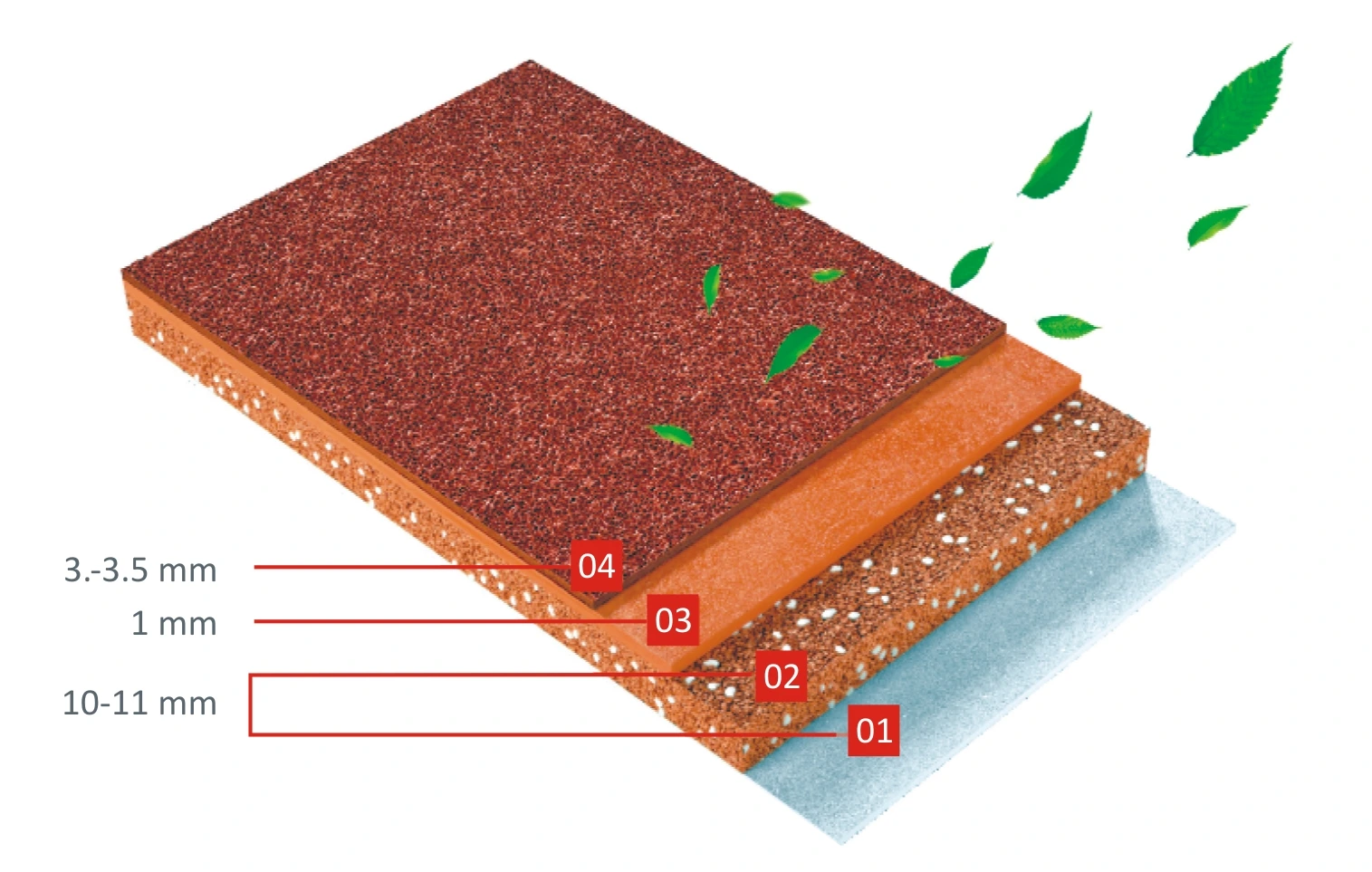

- Primer and Full-PU bottom Layer coating

- Full-PU body layer coating by two times

- Full-PU surface layer coating with EPDM broadcast or Spray-coat Layer on top

Specifications for Athletic Running Track Flooring

| Technical Specification | |

| Primer Layer (Concrete)

Seal Layer (Asphalt) |

DESMOTOP-RR 2012 PU primer

Latex Seal Layer Material (add sand and cement) |

| Bottom Layer | DESMOTOP C303 Elastic Full-PU Material

SBR Rubber Granule (Optional, 2-4mm) |

| Middle Layer | DESMOTOP C303 Elastic Full-PU Material

Rubber GranuLe (Optional, 2-4mm) |

| Surface Elastic Broadcast Layer | DESMOTP C303 Elastic Full-PU Material

Broadcast EPDM Granule (1-4mm)

|

| Surface Spray-coat Layer

|

DESMOTOP C301 PU Spray-coat Material

EPDM Granule (0 5-2mm±1-3mm or 1-4mm) |

| Surface Self Texture Create Spray-coat Layer |

Red PU Self Texture Create Material |

| Color Protect Layer (Optional)

|

Colorful Si-PU Surface Layer Material |

How is a Full PU Athletic Running Track System Made?

EPDM Broadcast or Spraycoat Top Cover With EPDM

- An in-situ rubberized crumb layer and a two-component flexible polyurethane elastomer comprise the Full PU Track surface.

- The wearing course surface for sporting tracks is made of a layer of polyurethane resin binder and colored EPDM rubber crumbs that are cast into the uncured surface, forming a durable polyurethane running track.

- The track is broadcast with EPDM rubber or a special colorful spray-coat material mixed with EPDM rubber. All markings, track layout, and track lines are up-to-date with the most recent version of the IAAF rules and regulations.

- The most popular color for the rubber EPDM granules broadcast is red, which is also known as the tartan track color Full PU Track. Other colors include blue and green.

Full PU Running Track System Construction Steps

- Primer and Full-PU bottom Layer coating

- Full-PU body layer coating by two times

- Full-PU surface layer coating with EPDM

Benefits of Full PU Athletic Running Track Flooring System

- Great durability

- Flexibility that boosts energy

- Excellent color stability

- It is very resistant to wear and has excellent elasticity

- Resistance to aging

- Resistant to ultraviolet light

- Low density provides superior coverage

- Great for wet-poured safety playgrounds

- Long-lasting pliability

- You can change the area and elasticity to a high degree

- Resistance to spikes is maintained even when subjected to prolonged stress

- It is recyclable, safe for the environment, non-polluting, and not toxic

- It can be installed both indoors and outdoors

- Electrical insulation

- Resistance to corrosion

- Impact resistance

- Installation and maintenance are easy

When it comes to a top-tier, premium running track specification system, Polyurethane Athletics Track Surfaces are ideal. These systems are the preferred choice for those seeking the best in athletic running track flooring, thanks to their unmatched quality and durability. For reliable solutions, choosing an experienced athletic running track manufacturer ensures long-lasting performance and sustainability.